In order to quell the vicious rumors that my liver has sought political asylum in Sweden, I figured it would be appropriate to document one of the exciting days of my life. I will spare you the hours of lecture that would be incredibly interesting if the room wasn't stifling hot. I will also forsake you the pleasure of describing how the department thought it would be a good idea to do tasting panel right before we had a lab working with fire and razor blades. Today...we brew.

You have two classes for Wort Boiling, Fermenting and Maturation. One involves an intro distilling where we take a fermented wort and process it through our two glass stills. The other is brewing the beer (that will later be used in the tasting panels). Both are all-day affairs where we get up at 8am and work until 4pm with the occasional break in between. So, here we go. An In With Bacchus Guide to My Life.

We start out here, at the front door of the brewery. It is festively decorated with the "International Brewing and Distilling Science Brewery", like everything inside is dipped in gold and run by butlers. It's not. It's run by grad students who need a degree.

We then enter the brewery. It is shiny and pretty, like a penny in the sun. Oh look, our sign!

Aww, hello department of ICBD. I love you, even though you take all my money.

Hello cereal cooker!

Hello mash tun/wort kettle/whirlpool filter!

Hello lauter tun!

What's that, fermentation tanks? You're woefully empty? Be patient, my sweet. Tender loving beer is on the way.

Here at the ICBD, we take drinking seriously. We are professionals. We evaluate for taste, color...and a bunch of other stuff too. See? We even have our own tap.

And look at our bottle collection.

Oddly enough, it doesn't scream "frat house". More "my brain is suicidal and my liver is a masochist". Same thing, right?

Ok, ok, let's get down to business. To defeat...the Huns. And by Huns, I mean sobriety. We start out by forming up our mash bill. Our first beer is a "premium" lager. First we need some corn grit (8 kg).

And then some crystal malt (.577 kg).

And then we take our big ole bag of lager malt (24.4 kg) to...the mill room!

This is our 2 roll mill. Technically, it's meant for agricultural (read: cow food) use but we fudge it a bit. Our efficiency isn't so hot but what the hell, it's cheap and it didn't have to be custom made. We mix the crystal and pale malt together in the hopper and turn the sucker on. It's pretty loud and it gives off a lot of dust that leaves us all coughing. We get a pretty coarse grist out of it, due to the fact that there's only 2 rollers, but it's adequate for us. Technically, anything we make here we can't drink. It has to be dumped down the drain. But we can do quality assurance tests. To, y'know, make sure it's tasty. We then take the two bags of grist and put them into our mashing unit.

The mashing unit above consists of a variety of things. The big blue section is a hopper with a screw in it. The corn grit is loaded into the hopper on top. The corn grit then falls into the grooves of the screw which is turned by a motor in the back. This pushes the grist forward at an even rate into a cylindrical cone where it is mixed with hot liquor. Like this!

Wait, hot liquor? No, not scalding hot Jamesons. Much to my utter confusion (and slight disappointment after all the signs) liquor is water in the industrial brewing world. This delicious porridge like substance is then pushed into the cereal tank by the pump on the bottom and this hosing attached to it.

You can actually see it speed by in the clear section of hosing that they installed. We then cook the cereal for some time to break down the starches in it (we rise by 2 degrees C per minute until 85 where we hold for 5 minutes, then boil to ensure starch breakdown). We then change the hose location (everything is pushed through hoses or piping) and fill the hopper with our malt grist. The same thing happens as with the corn and we then pump this into our mash tun/kettle. This gets a delightful 48C rest to activate the enzymes (I won't bore you with this part). After, we then add the cooked cereals (coooorn) to the mash tun. We do it this way that way the extreme heat of the cooked cereals (which was boiled) doesn't kill off the enzymes we need to break down the starches in the malt. Then we rest at 65C to deactivate the previous enzymes and engage new ones. We let it sit for 45 minutes while we go get lunch.

We come back to this.

Ewwie? Ewwie! No, sir or madame, delicious. This is the sugary sweet mash. It's been percolating for 45 minutes, stewing in its own juices (enzymes) to form a deliciously sweet liquid. It's almost like a thin porridge. Very tasty. Then we increase the temp from 67 to 71 and perform...

The iodine test. Iodine reacts with starch (which is not what we want) but not with sugar (which is what we want). So, a heavy starch solution (top left) turns squid ink black but the all sugar solutions (bottom right) are squeaky clean! This means that we've gotten all of the fermentable sugar we can out of it so we can filter out all the chunks. How do we do this?

The lauter tun. Basically it's a huge tube with a false bottom. The bottom plate is perforated so that the little tidbits of malt don't fall through. I'm sure you're asking "but there will be pieces smaller than that!". It's true...but here's the cool part about malt. It forms its own filter. We broke down the endosperm, the sugars that the plant would use to sustain itself after germination but before it has grown chloroplasts (component of chlorophyll for photosynthesis). We let the barley seed think that it's going to get to grow so that it germinates and begins breaking down all of the starches to long chain sugars it an use to fuel itself. But then we bake the shit out of it and kill it. This means that it broke down all of the sugars for us but it can't use them ('cause it's dead). The enzymes needed to do this are still in the grain so when we heat it up, these enzymes reactivate and break the sugar down even further. What's left is the hull/husk and variety of other shit that doesn't get broken down. These beautiful little bits end up forming a cake at the bottom of the lauter tun that filters the smaller particles.Here's the lauter tun filling with the chunky mash.

You can see those little particles swirling around. Those will be the filter later. In the meantime, we decided to multitask and do some quality assurance. This is a stout that we weren't sure would pass the muster.

It was good but I heard a funny tale. I heard that beers occasionally will get better the closer to the bottom of the glass you get. Something about the "awesome" having a higher density than the beer so it all sinks. Gonna have to pour another glass just to test this theory.

I think this hypothesis is correct. However, being a true scientist, a sample size of two just isn't enough. Three should do it.

Perfect. Hypothesis = delicious.

After quality control, the lautering had finished. We'd lautered first (by recycling the original wort back into the tank until it ran clear through the tubing at the bottom) and then sparged (after we drained the wort into the kettle we then started to spray hot water/liquor over the grains to get every sugary bit). Here's a good picture of the separation of the soon-to-be wort and the grain cake at the bottom.

See? Forms its own filter.

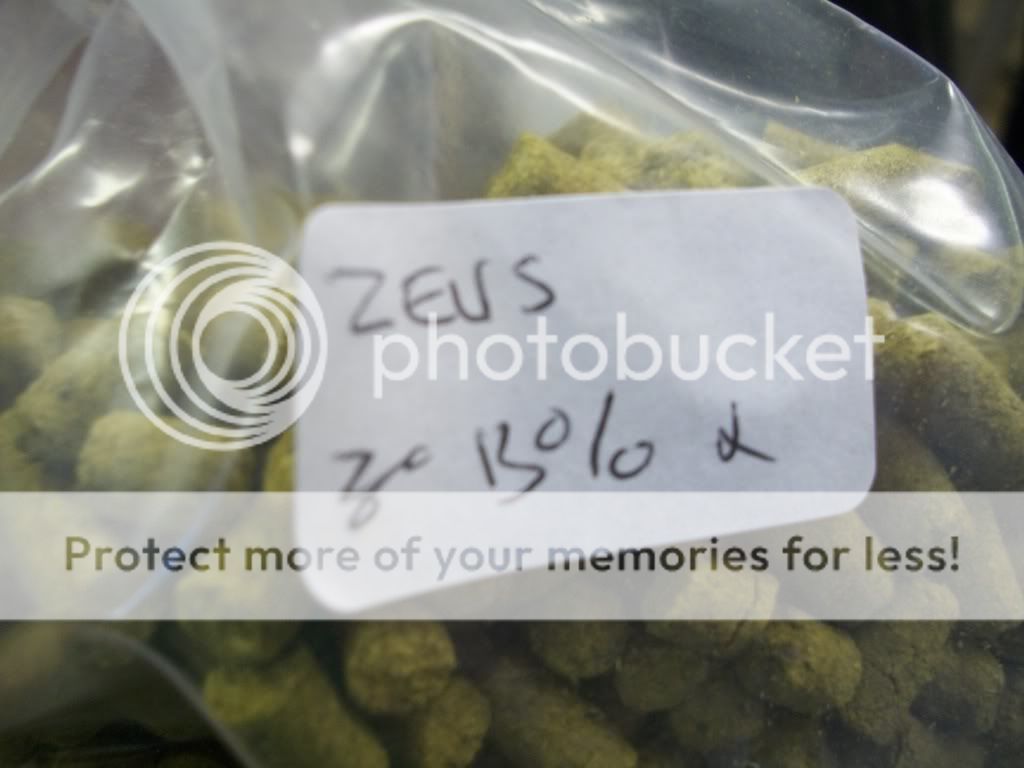

So, we've got our wort (clarified mash). Now we boil the shit out of it. It's just a hop, skip, and a jump to the finish, now. Emphasis on hop. HAHA, I MADE A FUNNY. We use two types of hop on this one: Zeus and Tettnanger.

The Zeus were our bittering hops, which are boiled for the entire duration to give the beer it's bitter flavor.

The Tettnanger were the aroma hops: added in the last few minutes of boil to provide aroma to the beer.

We boil and boil for an hour while we all go take a break in the form of a cuppa and a read of the newspaper. When we come back we finish up things. We first clean the lauter tun by removing the bottom and watching as all that crazy grain leavings fall to the floor. Here's the cake at the bottom:

And here's the cake on the floor:

The hot, hoppy wort is sent across the room (via pipes) to the plate chiller.

The hot liquid enters from one way and cold water enters from the opposite, cooling the liquid down before it enters the fermenter. We also add oxygen to it to promote yeast growth, even though you don't want oxygen after you ferment. Finally, it gets sent to the fermenter and we pitch the yeast (a Tennents lager yeast).

So, that's the day in a nutshell. For those of you who still say that I don't do a damn thing in this degree, you're wrong. So wrong it hurts me!

I take pictures.

How many gallons will this produce at full capacity?

ReplyDeleteI believe it was 200L.

Delete